Overview:

Developed a semi-automated gantry system capable of planting seeds in a grid layout using a combination of linear motion, soil displacement, and seed dispensing mechanisms. The system operates with three linear drives, a pulley system, and two actuators:

-

A rack-and-pinion tool to dig planting holes

-

A 3D-printed seed dispenser, actuated by a solenoid

Required tools and technologies: SOLIDWORKS, 3D Printing, Laser Cutting, Drill Presses, Stepper & Servo Motors, G-Code, Solenoids.

Your Title Goes Here

Design:

-

Collaboratively designed all mechanical components in SOLIDWORKS.

-

I was responsible for designing and printing the middle slider components, which accurately aligned the belt and aluminum bars using press fits.

-

My teammate designed the end mounts for pulley and bar connections.

-

For the actuator, we each prototyped a solution:

-

I proposed a hopper-style dispenser with a solenoid-driven gate mechanism at the base.

-

My teammate designed a mountable system for a commercial seed dispenser, also actuated by solenoid.

-

Both solutions were evaluated for final implementation.

-

Fabrication:

-

Most parts were 3D printed, with minimal manual machining (e.g., using a drill press to correct hole dimensions).

-

Assembly precision was critical, especially due to tolerance issues from 3D printing such as material warping and fit inaccuracies.

-

Some components required post-processing through filing or reprinting for improved fit and stability.

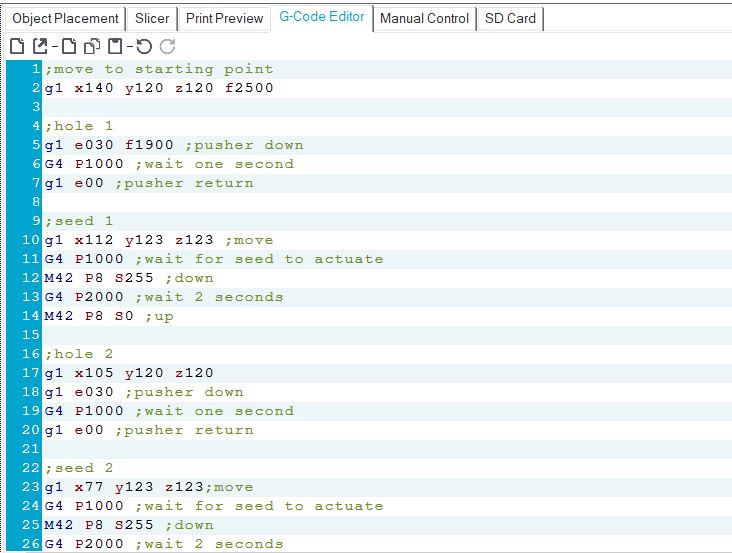

Programming & Automation:

-

Used G-Code in Repetier to control all three stepper motors (X, Y, Z axes).

-

Enabled synchronized or independent motion across the gantry for precise positioning.

-

The rack and pinion actuator handled vertical movement to punch holes, while the solenoid-actuated seed dispenser provided a half-degree of freedom on the Z-axis.

-

Created an automated sequence to:

-

Move to a planting location

-

Dig a hole using the actuator

-

Position the seed hopper

-

Dispense a seed

-

Repeat for a 2-row by 4-column planting pattern

-

Return to home position and terminate

-

See video demonstration of project here: https://drive.google.com/drive/u/3/folders/1ADtxkjpBTxIGR8mxQMStaJB8VEgogqoY