Design & Simulation:

-

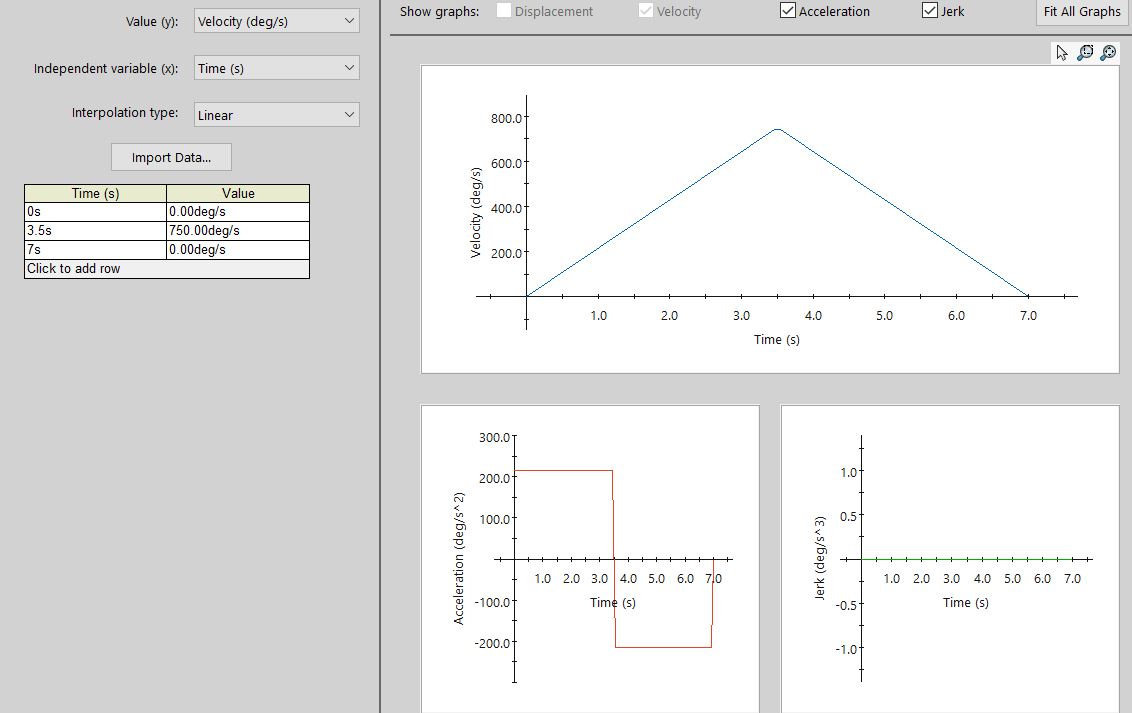

Created an initial cart concept individually in SOLIDWORKS, using Motion Analysis to simulate performance.

-

The prototype featured a sled design pulled via a Rack and Pinion system, achieving a 10-ft run in 7 seconds at a peak velocity of 800°/sec.

-

Early design iterations lacked rubber padding, which could have improved stability and speed by increasing surface friction.

Fabrication:

-

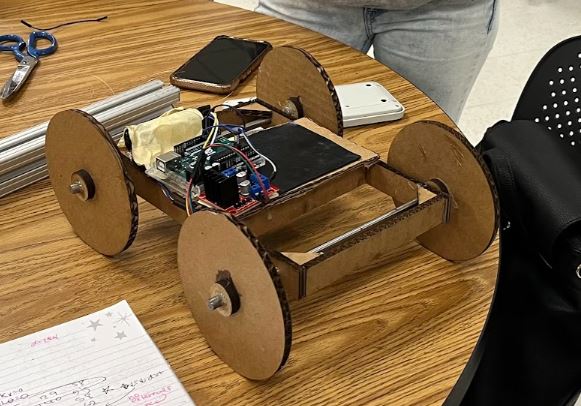

Constructed using cardboard and plywood from EPIC stock; critical components (wheels, gears, spacers) were laser cut.

-

Hot glue was used for cardboard connections, and super glue for wooden spacers and friction pad attachment.

-

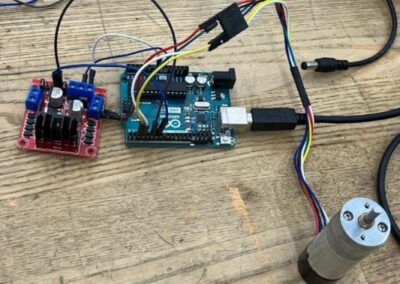

The motor system (including DC motor, H-Bridge, and Arduino) was secured with painter’s tape.

-

The drivetrain featured axles and a gear system, a pivot from the original plan to use a 3D-printed spool that wasn’t completed in time.

One major design change was that we were initialy going to 3D print a spool and use that to pull the cart. However, since the print was not done by Monday, we instead had to change to using gears to power the cart like a car rather than pulling it.

Testing & Performance:

-

Final prototype transported the foot-long aluminum bar across 10 feet in 5.5 seconds, outperforming all other teams.

-

Demonstrated system stability and consistent performance under load, with the rubber pad significantly improving grip.